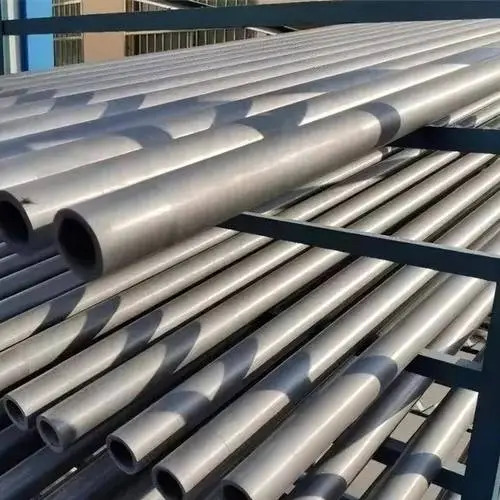

Material Properties of Silicon Carbide Rollers:

Hardness and Wear Resistance: Silicon Carbide (SiC) rollers exhibit extremely high hardness, surpassing even that of steel. Their hardness rating is greater than Mohs' nine, making them extremely wear-resistant. Their wear resistance is reported to be ten times higher than that of alloy steel and wear-resistant cast iron.

Corrosion Resistance: Silicon Carbide (SiC) rollers are resistant to corrosion from both acidic and alkaline substances.

High-Temperature Resistance: Silicon Carbide (SiC) rollers are sintered at 1500┬░C, making them capable of operating in temperatures up to 1600┬░C. They also possess excellent thermal conductivity with a thermal conductivity coefficient of 12 or higher.

Application in Kilns:

Durability: Due to their excellent wear resistance, Silicon Carbide (SiC) rollers in kilns can last for extended periods, reducing the need for frequent replacement.

High-Temperature Performance: Silicon Carbide (SiC) rollers' ability to operate at high temperatures ensures they can handle the rigorous conditions in kilns.

Industrial Uses: Silicon Carbide (SiC) rollers are widely used in kilns for the production of various materials, including lithium battery electrodes, magnetic materials, ceramic tiles, and building ceramics. Their durability and high-temperature performance make them an ideal choice for these applications.

Conclusion:

Silicon Carbide (SiC) rollers, with their superior hardness, wear resistance, corrosion resistance, and high-temperature performance, are an excellent choice for kiln applications. Their durability and ability to handle rigorous operating conditions make them a valuable asset in various industrial processes.

Contact: Sales Dept.

Phone: (86) 186 0101 9114 (ER only)

Tel: (86) 10-52868200/01/02/03

Email: sales@sinomaterial.com

Add: 5-301, Lincui West Road, Chaoyang, Beijing China